Pallet flow racking is a high-density storage system that uses slightly inclined roller tracks to allow palletized loads to move smoothly by gravity from the loading end to the picking end.

Need help? Call us at 800-835-1133

Pallet flow racking is a high-density storage system that uses slightly inclined roller tracks to allow palletized loads to move smoothly by gravity from the loading end to the picking end.

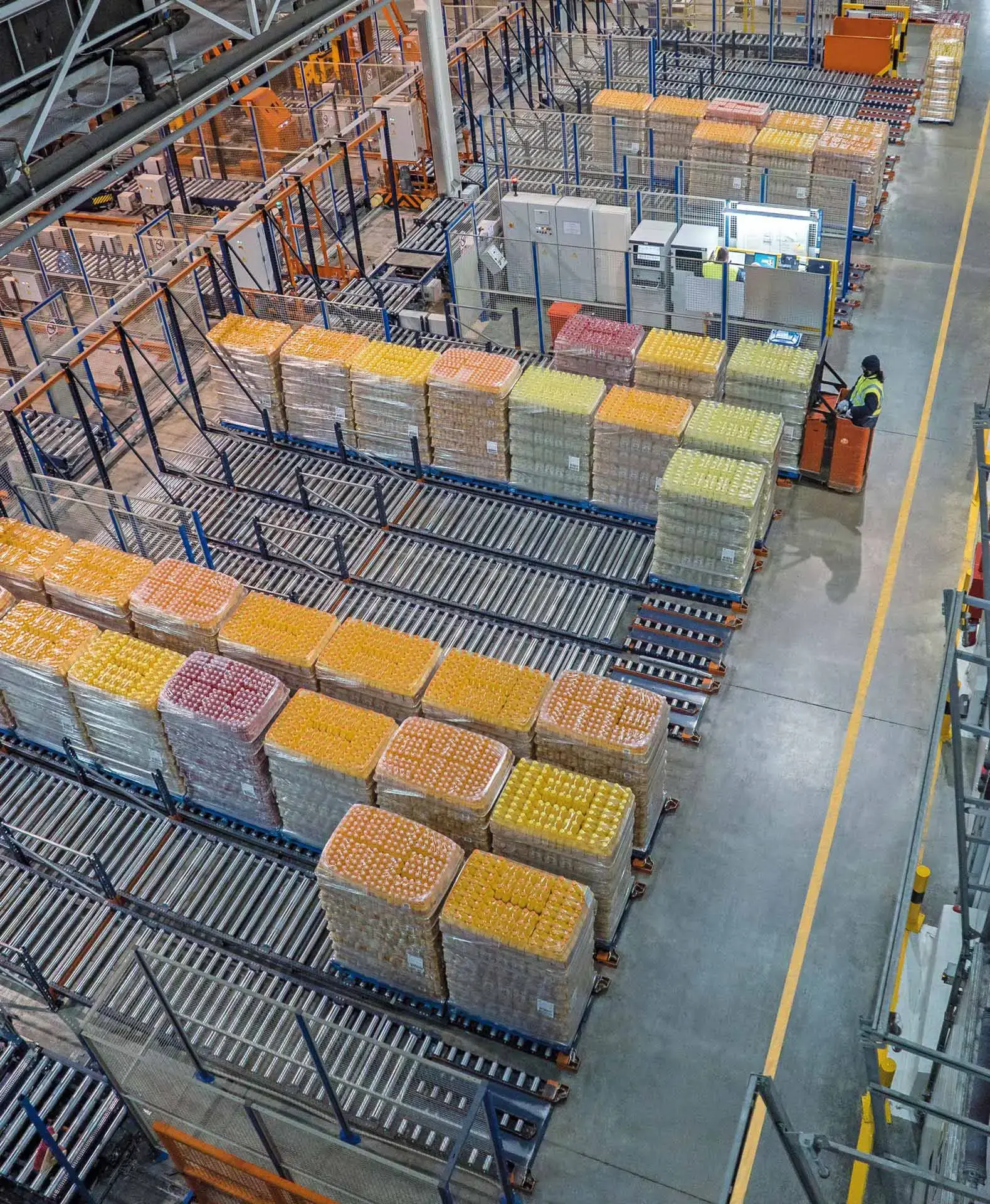

Pallet flow racking is a high-density storage system that uses slightly inclined roller tracks to allow palletized loads to move smoothly by gravity from the loading end to the picking end. Pallets are placed at the higher end of the channel and automatically roll down to the opposite side, ready for retrieval.

This system eliminates the need for intermediate aisles, significantly increasing storage capacity. It also supports the FIFO (first in, first out) inventory method, making it ideal for efficient stock rotation and inventory control.

We also sell, service, and rent forklifts, scissor lifts, pallet jacks, and more.